New Product Launch | Tool Solution for Gear Honing

SNSTC 2025-03-28

SNSTC has launched a brand-new series of high-precision gear honing wheel dressing tools, designed to compete with imported alternatives. These tools promote a comprehensive upgrade in gear processing technologies for automotive and robotics applications while accelerating the localization of the industrial supply chain.

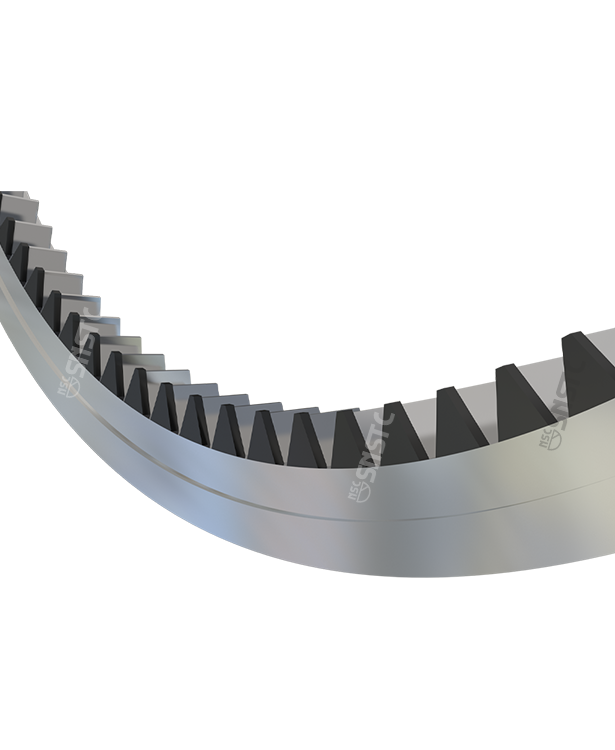

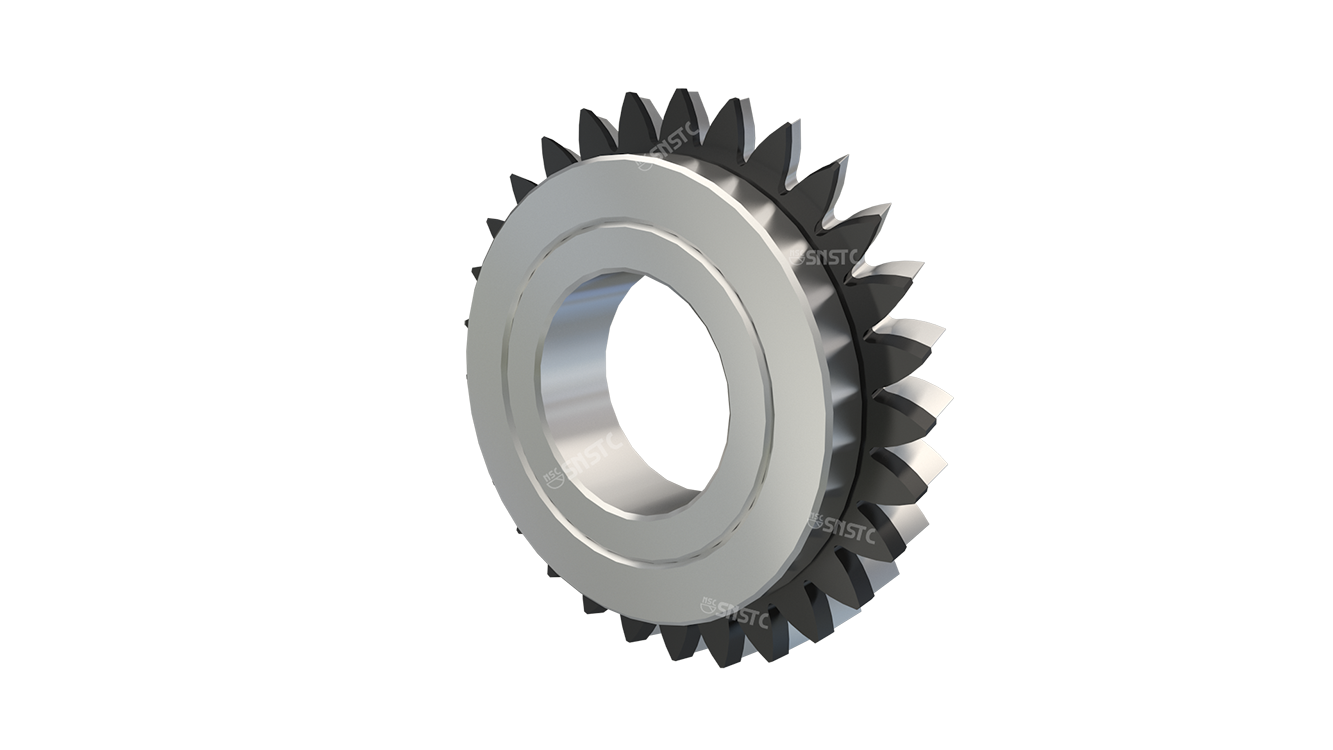

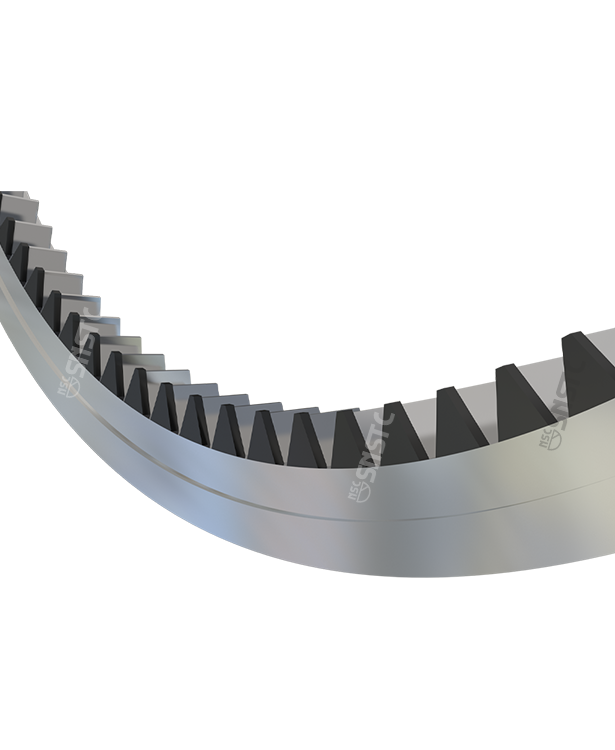

High-Precision External Gear Honing Wheel Dressing Tool

This specialized dressing tool is specifically developed for gear transmission dressing. It features a unique geometric structure that generates a continuous and uniform surface edge along the tooth profile. As a result, During the dressing process, a tooth flank with exceptionally high surface quality is transferred to the honing ring and ultimately to the workpiece surface.

Compared to other similar processes, this technology optimizes the reproducibility and surface quality of the tooth direction while further reducing the NVH levels of gear components. In contrast to traditional diamond honing wheel dressing tools, it ensures higher precision and more stable profile shape.

Advantages

1.Unprecedented high profile accuracy and tight tolerances

An extremely fine machined surface can be achieved, further enhancing the surface quality of the final product. By using this dressing tool correctly, reliable and continuous mass production can be maximized.

2. Freely customizable tooth profile

Fully customized tooth profile structure, locally produced to align with supply chain dynamics, ensuring short production cycles and fast delivery

3. Better reproducibility and surface quality.

The entire high-quality surface is transferred from the dressing tool to the honing ring surface and subsequently to the gear workpiece surface.

4.Superior Surface Roughness

Achieves sub-micron level surface roughness.

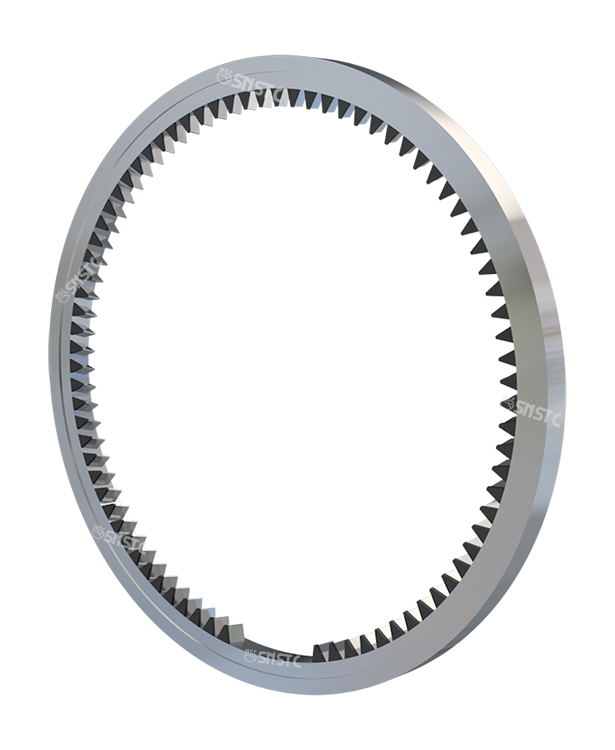

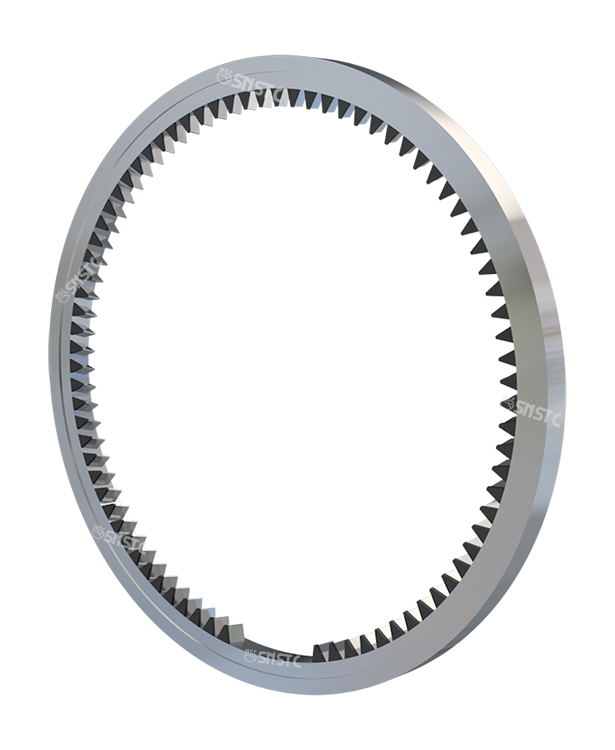

Internal Gear Honing Wheel Dressing Tool

The dressing tool for internal gear honing wheels, developed simultaneously, features similar processing characteristics, providing high-quality and consistent machined surfaces while maximizing reliability and continuous mass production.

If you are interested in this tool,Welcome to contact with us:

Service Hotline: 021-59155664

Contact Number: 17721195368(Wechat ID)

Visit our official website for more exciting information:

Follow us

Follow us